Programming devices

Different methods can be used for programming the robots, all with a Windows-based interface, installed on an industrial PC or Teach Pendant.

VR Tracking

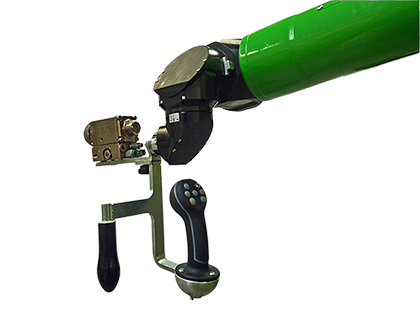

After many years of experience in the self-programming of painting robots, CMA has developed the evolution of the self-learning system. Instead of moving the robot as traditionally happens, a special joystick is used, very light and easy to maneuver, on which the spray gun itself is fixed.

The trajectories are acquired by a series of sensors and stored to create the complete paint program. Finally, the operator manually paints an initial piece, so that the trajectories can be replicated by the CMA robot.

Joystick for self-learning

With these programming devices, painting cycles can be performed directly on the workpieces, which are stored and coded within the controller. The programs created in this way can be called up in the future via an interface with the possibility of modifications. They can also be used for point acquisition in point-to-point programming.

The main commands are:

- Opening one or more guns

- Start-Stop Program storage

- Program storage

- External signals management

- Workpiece rotation management

- Point acquisition in PTP programming

Mobil Panel

Hardware

The programming unit is equipped with an 8” colour touch screen display, with 800x600 pixels resolution. Equipped with a “dead man” safety device with three possible different positions: one for point to point programming, one for the emergency switch, and a key, to switch the operating modality between teach and auto.

For programming, beside the touch screen monitor, a keyboard and six-degrees of freedom analogic joystick can be used, to perform the most frequently used functions.

The mobile panel is equipped with a 10 meters long cable to be used near the robot.

Programming unit

In addition to the monitor, a keyboard can be used for programming, which provides the most frequently used functions, and an analogue joystick with three degrees of freedom for the manual movement of the robot.

Off Line

The offline programming system allows painting programmes to be created using a 3D model of the sample piece. A simulation of the cycle is displayed with graphic effects that allow the process to be optimised. All the parameters can be set directly on the computer and then the programme is exported to the robot. The development environment is the same as the one used on the Mobile Panel for PTP programming. The programme can be exported from the robot to a Personal Computer in order to make changes so that the robot does not have to be stopped.