SOLUTIONS > CERAMIC

CERAMICS

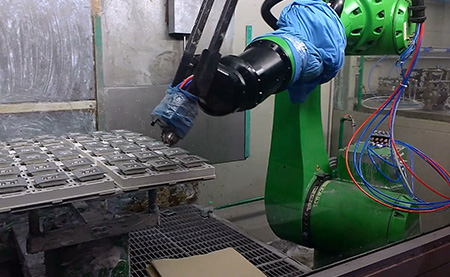

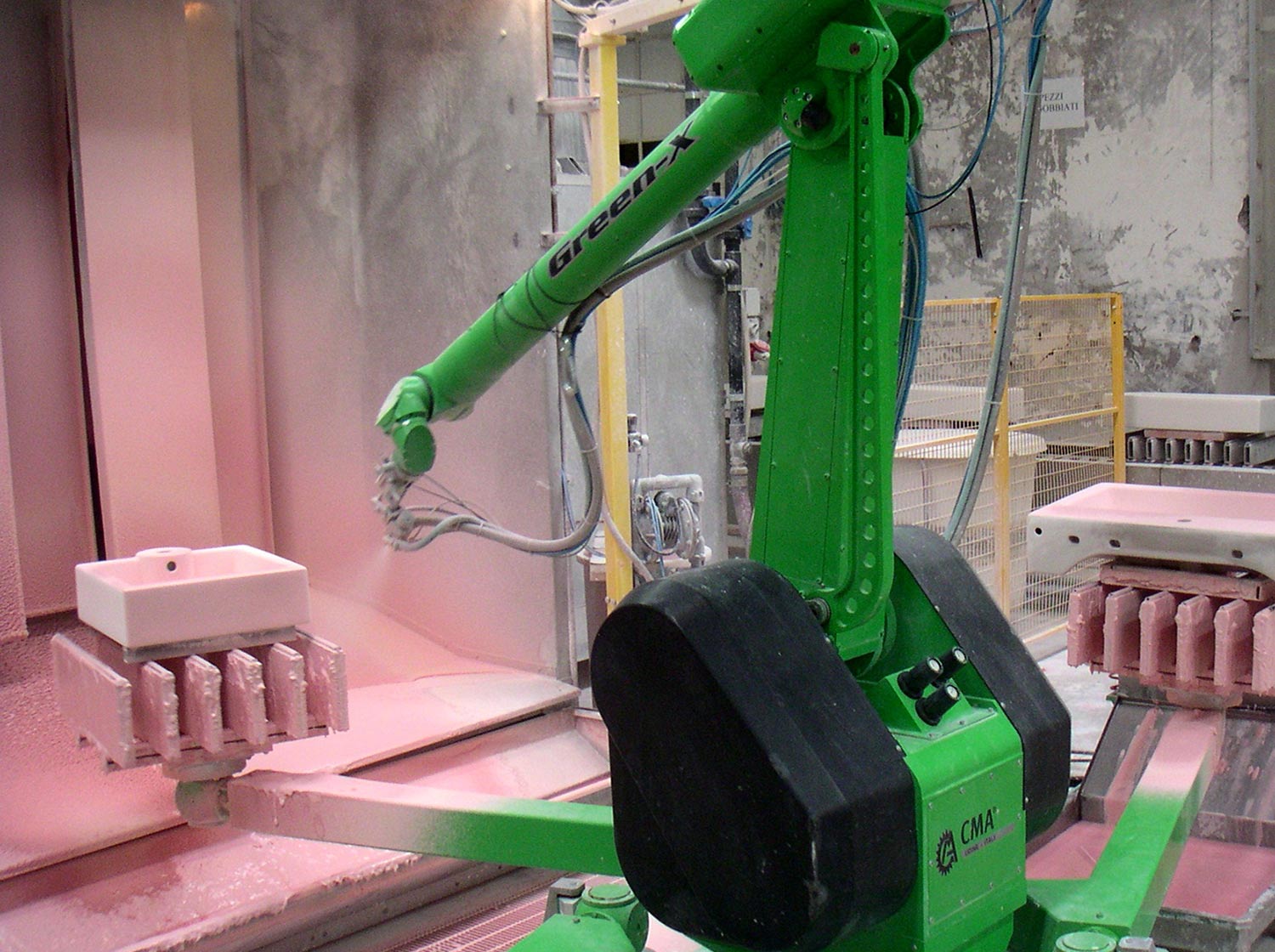

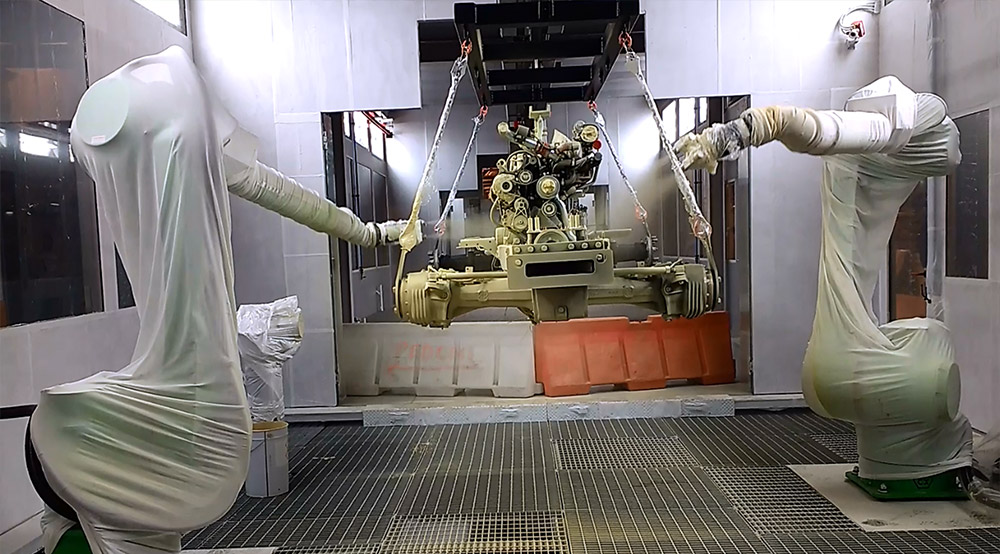

Complete systems for the glazing of sanitary ceramics, with automatic part recognition systems.

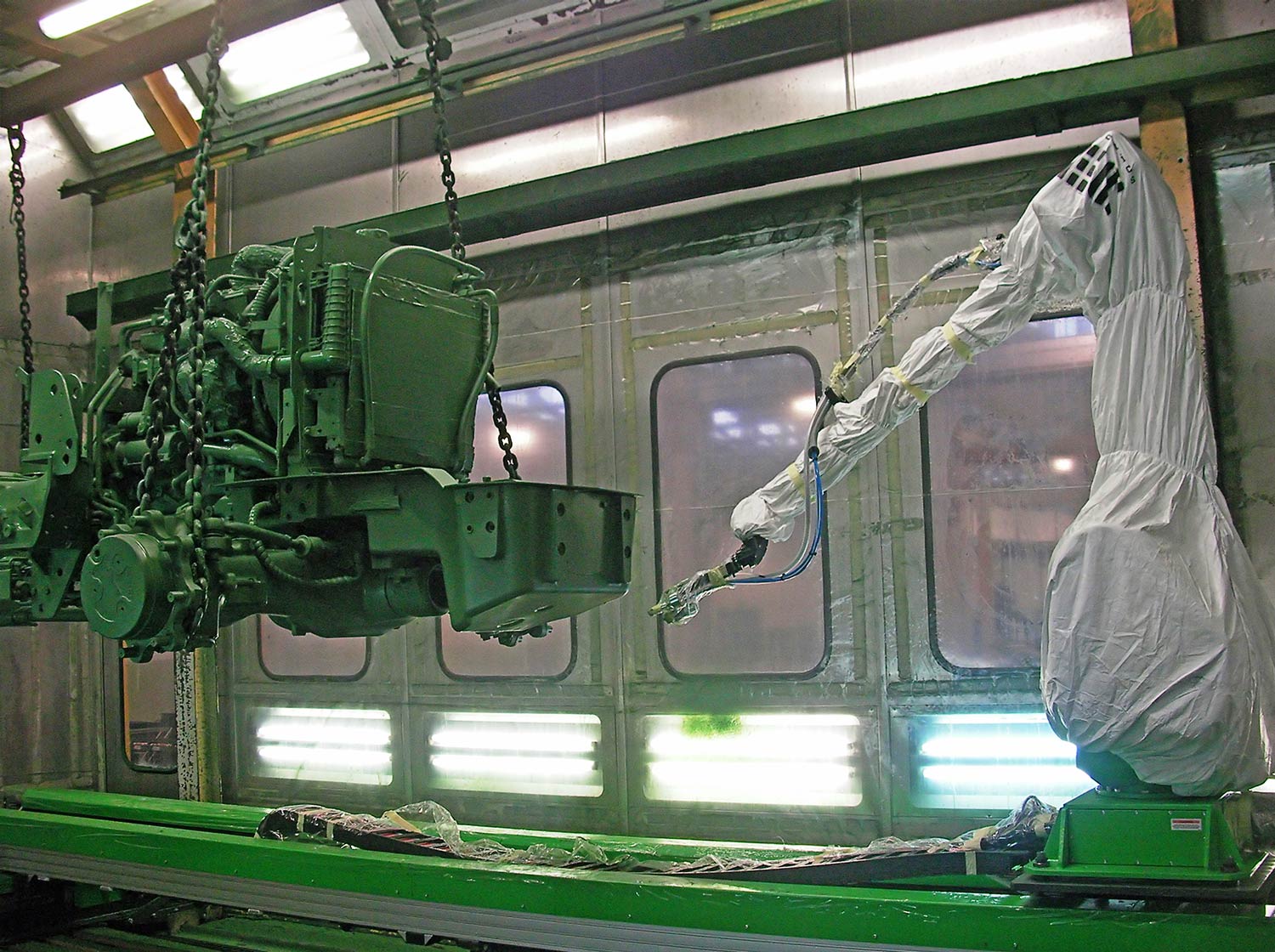

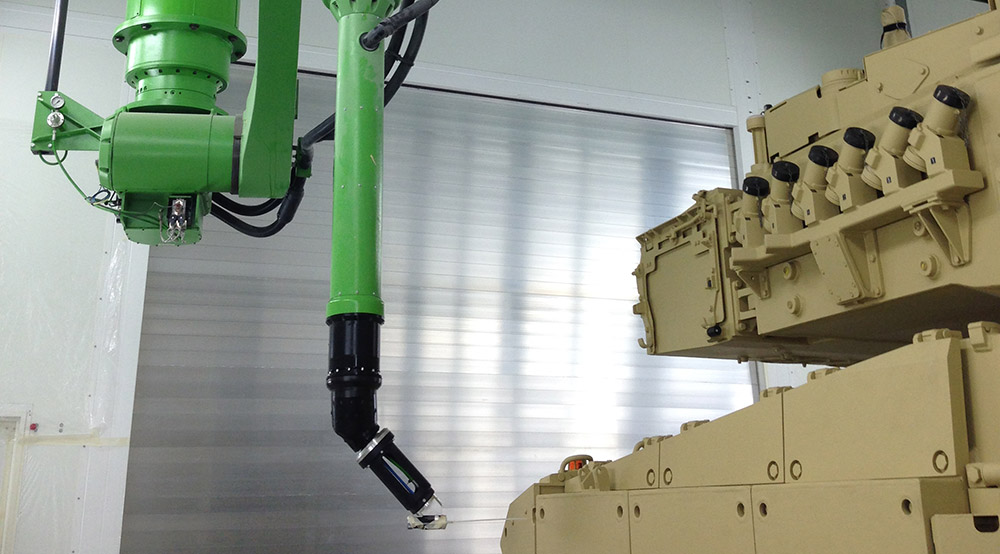

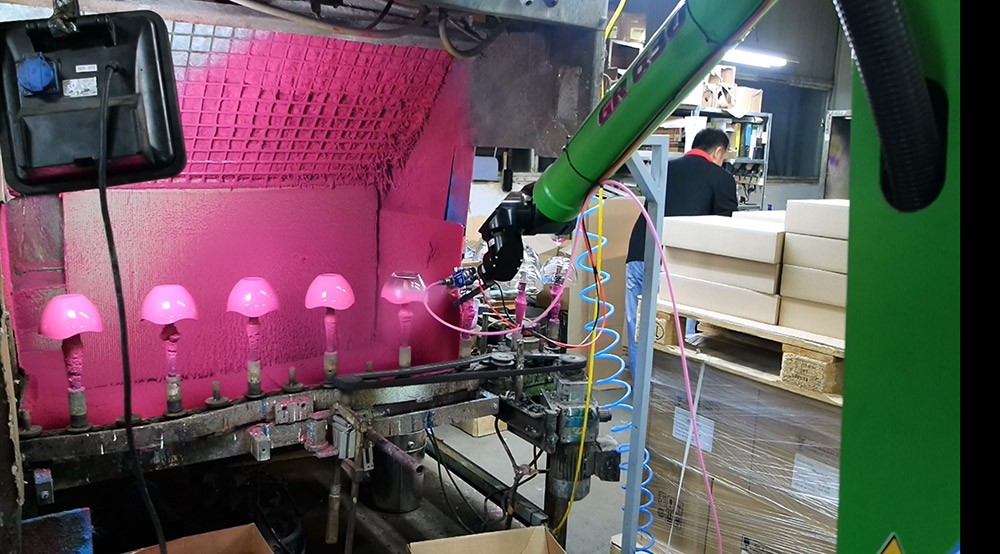

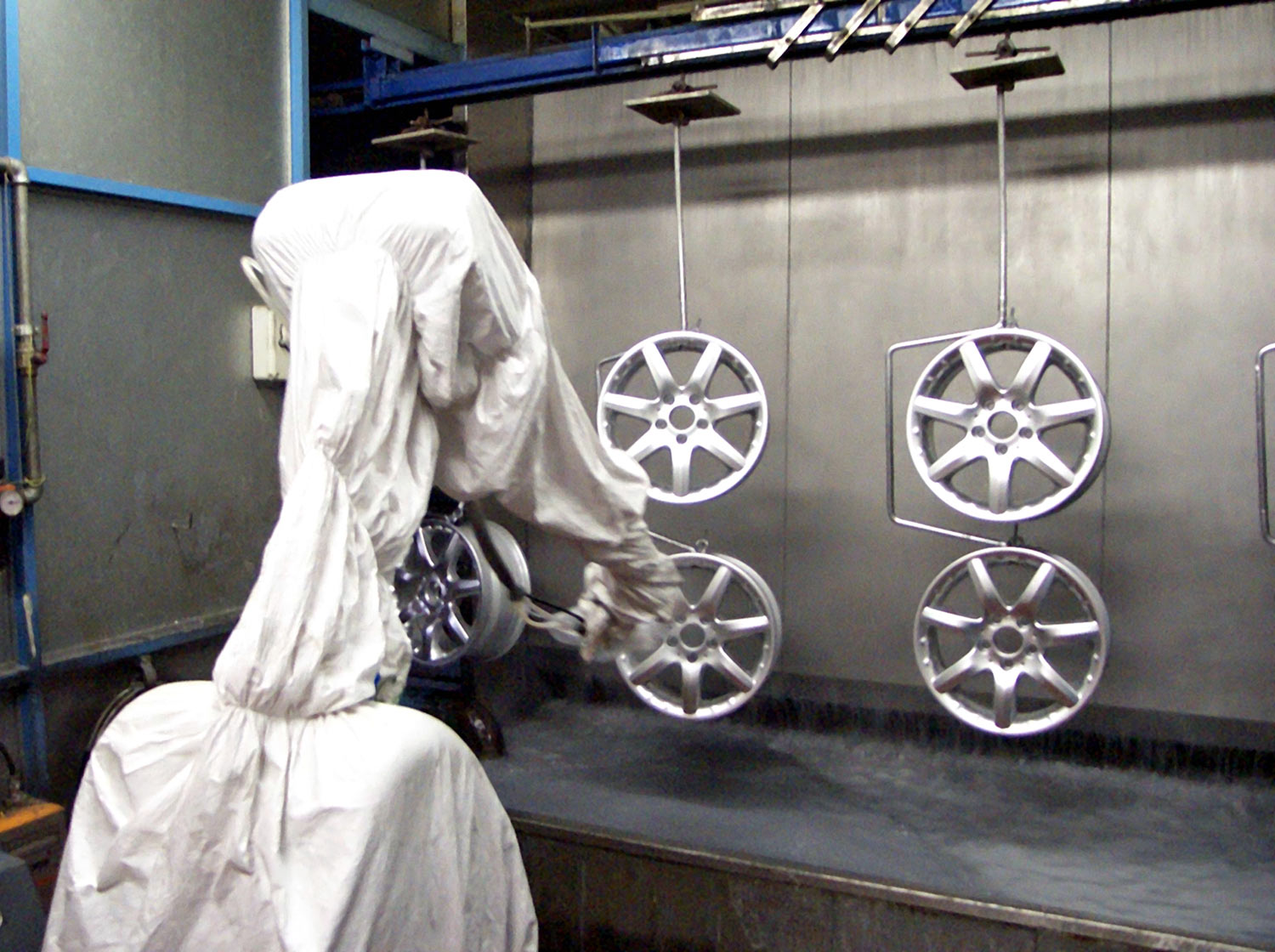

CMA Robotics has been on the market for over twenty-five years and has developed advanced spraying robots for many sectors, so also for the glazing of ceramic products, earning the trust of customers, the best innovative solutions on the market have been designed. Using the latest technologies CMA Robotics has designed complete lines that have immediately brought great advantages in terms of quality and production, minimizing human intervention, production time and avoiding paint waste.

CMA ROBOTICS deals with the glazing of ceramic products, from sanitaryware to shower trays, with automatic piece recognition systems, spray booths and everything needed for a complete equipment.

Below are some examples of projects carried out in the ceramic sector:

- Double sanitaryware glazing system equipped with: two spraying booths, two + two pre-testing booths, two corner telescopic transferers, two linear transferers and two glazing robots. Four operators are sufficient for the management of the system. Average production 60/70 pieces per hour;

- Shower tray glazing plant equipped with two spraying cabins, two + two pre-testing cabins, two telescopic corner transfers, two glazing robots, one handling robot. Three operators are sufficient to manage the system. Average production 40/50 pieces per hour;

- Sanitary glazing installation and shower trays equipped with: one spraying cabin, one corner telescopic transfer unit, two linear transfer units and one glazing robot. One operator is sufficient to manage the plant. Average production 40/70 pieces per hour.

Watch the images and videos in this page for further details about the services offered by CMA Robotics for this sector.

For further information you can contact your sales representative.